The Innovative Edge – Bring Those Jobs Home!

June 5, 2018

The Innovative Edge – Bring Those Jobs Home!

by Rishab Rao

“The enterprise that does not innovate inevitably ages and declines.” – Peter Drucker

Jobs! Jobs! Jobs!

It is the age-old rhetoric of aspiring politicians, “Jobs! Jobs! Jobs!” Yet, in the U.S, the jobs seem to continue to move overseas, where the economies of labor and logistics are arguably more favorable. The truth is that politicians can do very little to bring those jobs back without drastic, economy-endangering measures. Often these measures take the form of penalizing domestic businesses for moving jobs overseas. This reaction is a Band-Aid solution that will struggle with longevity. Such forceful measures weaken the economy and competitiveness of the domestic market in the long run.

The decision to export the manufacture of a company’s products must remain with the business owner – as must the solution!

Domestic manufacturing costs, including labor, often cut deeply into product profitability, driving the decision to manufacture the product overseas. Yet, the decision is often a difficult one due to the loss of domestic jobs. Thus, patriotic conscientiousness is at odds with the juggernaut of profit growth. But, why can we not have both? The answer is we can! The key to growing the business’s profits and keeping jobs at home is innovative product simplification.

The Return of Swatch®

Until 1950, Swiss watch maker Swatch1 dominated the industry with over 80% of the global market. In 1951 the American company Timex introduced a cheaper alternative to the Swiss giant’s high-end, luxury watch. Timex aggressively captured market share from its Swiss competitors, decimating Swatch’s share to a mere 42% by 1970. A second wave of devastation for Swatch arose in the form of new competition in the East. Emerging watch makers in Japan and Hong Kong leveraged Quartz technology to introduce cheaper alternatives to Swiss watches. The 1970s was a brutal decade for Swatch, and by 1984 their global market share had dwindled to less than 15%.

The cheaper materials and manufacturing costs in Japan and Hong Kong began paving the path to Swatch’s grave. As W. Edwards Deming said “It is not necessary to change. Survival is not mandatory.” A change was needed for Swatch to survive, but the company had a choice: they could outsource their watch-making to the Far East where materials and labor were cheap, or they could redesign their products for cheaper manufacture in Switzerland. Swatch embarked on the latter.

The Swatch design team asked themselves, “Why can’t we design a striking, low cost, high quality watch, and build it in Switzerland?”2 The last part of that question greatly changed the design objectives. It forced them to abandon the idea of simply doing things “better” and begin doing things “different.” “Better” would not have achieved dominance over the new and cheaper competitors. “Different,” albeit requiring greater innovative effort up-front, had the potential to truly compete and even dominate the industry once more.

Among other strategic and tactical maneuvers, Swatch undertook the initiative to introduce a new line of watches. They redesigned their products for easier, quicker, and cheaper domestic manufacture. After much effort and perseverance, the results were magnificent. The Swatch redesign reduced direct labor costs from 30% to less than 10%3, making domestic manufacturing viable. Additionally, Swatch was now able to price their watch significantly more competitively in the market. The result was an unstoppable resurgence of Swatch’s dominance in the global watch market. The key ingredient in Swatch’s successful redemption was the team’s willingness to challenge itself to innovatively simplify product design to make domestic labor costs a non-significant factor.

Product Complexity

Product complexity is measured by the effort put into making and using a product. Factors that influence product complexity include the number of constituting components and moving parts, the number of tasks necessarily executed in its production and usage, the degree of difficulty of achieving a good quality complete unit, the cost of raw materials, durability during usage, etc. The greater the complexity the more difficult it is to produce the product, and, consequently, the greater the manufacturing cost.

Product simplification is a deliberate initiative to reduce the complexity of the product, both in making it and using it. Typically, the simpler the design of a product, the cheaper and quicker it is to manufacture. However, simplifying the design of a product requires an initial effort. Expending this up-front effort and time investment necessitates a trade-off – time-to-market versus product simplicity. The encouraging silver lining of investing the up-front effort in innovative product simplification is the additive nature of building innovative capability. The more mature the innovative capability, the less significant the trade-off, and the quicker the business gets at launching redesigned and newly designed products.

Businesses often place themselves under great pressure to launch a new (or newly redesigned) product as quickly as possible. This perspective purports that the sooner a product is launched, the sooner the business can begin to realize a return on the investment. While, this is true for the most part, it fails to consider the increased manufacturing costs with which the business will have to contend for the rest of the life of the product.

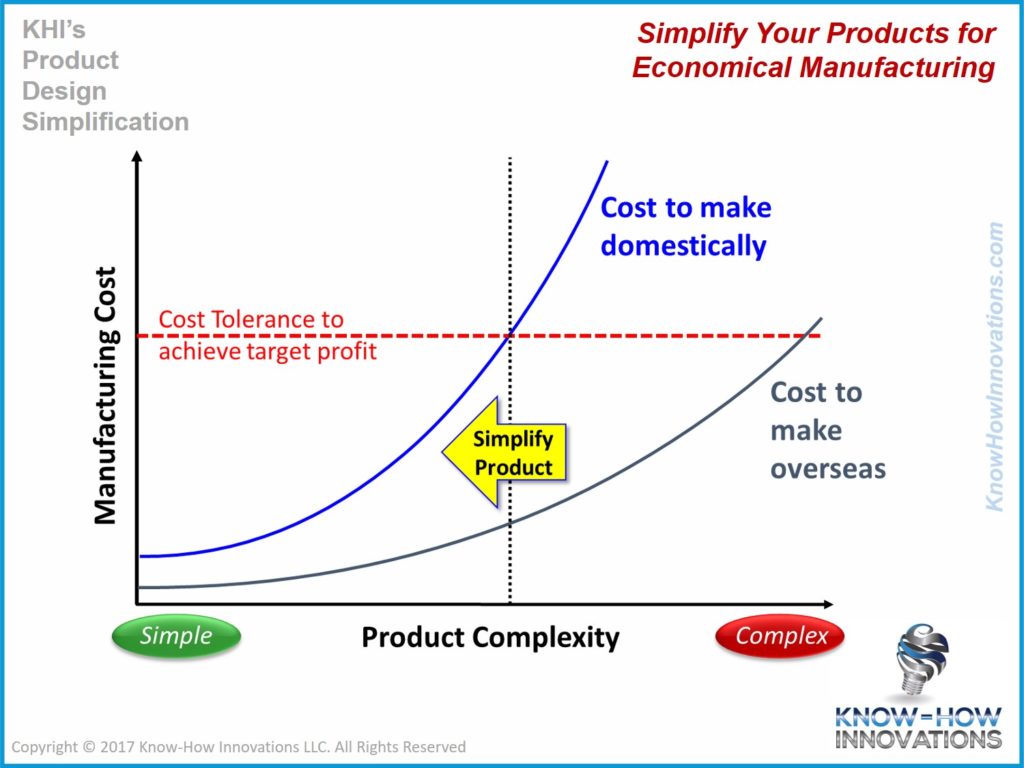

Simplifying the design offers an abundance of new options, one of which it the viability of domestic manufacture. The greater the product simplicity objective, the greater the innovative challenge. However, the greater the simplicity of the product, the greater the efficiency of manufacture, and the greater the potential for higher sale volumes and revenue. The objective of product design simplicity is to achieve a design such that the labor cost of manufacturing is irrelevant. For this to be successful, thought and research must be invested in identifying the cost tolerance – the maximum acceptable domestic manufacturing cost to achieve target profitability. Product simplification must achieve manufacturing costs under the tolerance.

Source: Product Design Simplification

But why should businesses care about where their products are made as long as the profitability is maintained? Because innovation capability is essential to the long-term sustainability of any business.

Atrophying Innovation

Increased globalization removes time and distance barriers for communication, commerce, and logistics across the world. Pockets of local economic advantage are more readily leverageable globally. For example, an American business can leverage European research capability, Chinese manufacturing, Indian software development, and an Australian marketing team to offer products to American consumers. The ease of harnessing global capability leaves dwindling incentives to keep those jobs within the domestic market. Given this global economic landscape, the decision to take advantage of economies overseas is inevitable, and in fact, an astute one. It is far cheaper and significantly more profitable to export operations overseas. However, the domestic labor economy inevitably suffers.

Cheaper overseas operations yield higher profitability. However, what is often overlooked is the hidden danger of atrophying innovative capability lurking beneath the buoyant waves of profitability. When Product Design is separated from Product Manufacturing, the result is the falling away of all manufacturing-related criteria in the product design process. The long-term effect of continuously exporting manufacturing is a systemic weakening of in-house innovative capability. Product designs become lazy when simplicity is not a priority criterion. There is simply no motivation to streamline the design of a product when, no matter the complexity it can still be manufactured cheaply overseas.

The problem is that atrophying innovative capability is a very real danger. Extrapolating past and current data indicates that the economies of the developing world will not remain cheaper than the developed world forever. Developing countries that currently offer preferential economies will eventually catch up and the balance will shift. For businesses to navigate this uncertain and treacherous terrain, they must maintain and hone their innovative capabilities. The survivability of a business in the future is directly proportional to its investment in innovative capability now. Designing products for simpler manufacturability is an exercise and investment in improving innovative capability.

Bring Those Jobs Home

In addition to improving innovative capability, product simplification lowers manufacturing costs, enabling businesses to bring much needed jobs back home. Leveraged properly, this has significant branding advantages and garners a great deal of domestic goodwill. Better employment rates increase spending power and fuel the domestic economy. A better economy leads to better sales for businesses. It should selfishly be the goal of every business to enrich their local economy.

Innovative product simplification offers multi-tiered benefits. The simpler the product, the cheaper and quicker it is to make domestically. This liberates capacity to produce greater volumes and the potential for greater revenue and profit. It may be challenging to achieve, but product simplification almost always yields better results than expected. It’s a choice. Start innovating… and bring those jobs home!

References:

- https://www.studocu.com/en/document/politecnico-di-torino/strategy-organization-and-marketing/lecture-notes/lecture-notes-case-study-the-birth-of-swatch-strategy-organization-and-marketing/966308/viewhttps://hbr.org/2015/12/what-is-disruptive-innovation

- “The Science and Art of Branding” by Giep Franzen and Sandra Moriarty, Chapter 3, Page 46.

- “Blue Ocean Strategy” by W. Chan Kim and Renée Mauborgne, Chapter 6, Page 133.